Özen Kompresör, yarım yüzyıllık endüstriyel tecrübesi ve geniş ürün portföyü ile güvenilir, verimli ve dayanıklı basınçlı hava çözümler sunar.

-

REKABETÇİLİKÖzen Kompresör müșterileri lehine hareket eder. Onlar için avantajlar sağlamak güçlü yönlerinden biridir.

REKABETÇİLİKÖzen Kompresör müșterileri lehine hareket eder. Onlar için avantajlar sağlamak güçlü yönlerinden biridir. -

DAYANIKLILIK & VERİMLİLİKÜrün portföyündeki tüm basınçlı hava ekipmanları en zorlu ortamlarda dayanıklılıklarını kanıtlamıșlardır. Kaliteli ve yüksek verimli hava üretirler.

DAYANIKLILIK & VERİMLİLİKÜrün portföyündeki tüm basınçlı hava ekipmanları en zorlu ortamlarda dayanıklılıklarını kanıtlamıșlardır. Kaliteli ve yüksek verimli hava üretirler. -

KALİTEYüksek ve hep aynı kalitede ürünler ortaya çıkarmak temel ilkelerindendir. Bu hedef doğrultusunda kalite politikasını sürekli geliștirir.

KALİTEYüksek ve hep aynı kalitede ürünler ortaya çıkarmak temel ilkelerindendir. Bu hedef doğrultusunda kalite politikasını sürekli geliștirir. -

GÜÇLÜ SERVİS AĞISürdürülebilirlik ilkesini esas alan Özen Kompresör ulașılabilir, hızlı ve güvenilir servisi ile müșterilerinin kesintisiz üretim yapmasını destekler.

GÜÇLÜ SERVİS AĞISürdürülebilirlik ilkesini esas alan Özen Kompresör ulașılabilir, hızlı ve güvenilir servisi ile müșterilerinin kesintisiz üretim yapmasını destekler. -

GÜVENMüșteri memnuniyeti odaklı çalıșma prensibi, Özen ile müșterileri arasında firma ve ürünlerine duyulan kalıcı güven ve sadakati yaratmıștır.

GÜVENMüșteri memnuniyeti odaklı çalıșma prensibi, Özen ile müșterileri arasında firma ve ürünlerine duyulan kalıcı güven ve sadakati yaratmıștır.

BASINÇLI HAVA ÇÖZÜMLERİ UZMANI

ÜRÜNLER

Fabrika (Merkez)

Konya Organize Sanayi Bölgesi

Büyük Kayacık Mah. 20. Sok. No: 4

42300 Selçuklu,

Konya – Türkiye

T: 444 6936 (444 ÖZEN)

T: +90 332 345 4245

F: +90 332 345 4248

Marmara Bölge Müdürlüğü

İOSB Süleyman Demirel Bulvarı

Heskoop İş Modern Sitesi

I Blok No:39 Başakşehir

İstanbul-Türkiye

T: 0212 803 22 22

Mesaj Gönderin

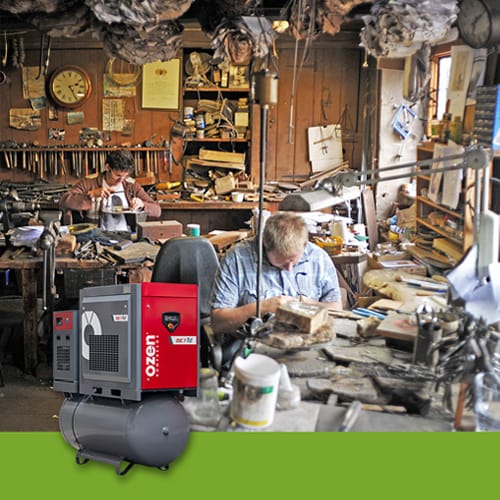

Hava Kompresörleri İle İşletmenizin Performansını Artırın

Özen Kompresör, basınçlı hava sistemlerinin üretimi, satışı ve servisi konusunda faaliyet gösteren sektöründe öncü bir firmadır. Uzun yıllara dayanan deneyimi ile basınçlı hava ekipmanları, chiller ve bunların yanı sıra geniş bir yedek parça seçeneği sunar. Alanında uzman ekibi ile müşterilerinin ihtiyaçlarını en iyi şekilde analiz ederek doğru kompresör seçimi, kurulumu ve bakımı konusunda profesyonel destek sağlar.

Ürettiği basınçlı hava kompresörleri, enerji verimliliği ve uzun ömürlü kullanımı ile işletmelerin verimliliğine katkıda bulunur. Farklı güç ve kapasitelerdeki kompresörleri, ürettiği kaliteli basınçlı hava ile petrol, madencilik, ilaç, otomotiv, kimya ve inşaat sektörü gibi alanlarda yaygın olarak kullanılır.